My error on the hitch height video

The summary is; I made an error on the Hitch Height video, describing the tandem-axle trailer on the as non-load-share, whereas it does have a load-sharing suspension of sorts, even if it wasn’t working well enough to actually do the load-share job.

However, the conclusions, advice and demonstrations are still correct which is why the video is still up. Despite the fact the tandem has a load-share suspension, it doesn’t work very well and so demonstrates my point about towball masses varying with hitch heights. The main point of the video is:

Varying the hitch height so the trailer doesn’t tow level is a bad idea for many reasons, and the towball mass will change according to hitch height, and does so differently depending on what sort of trailer you’re towing.

Someone else pointed out that towball load weight is the correct term, and I agree, but “towball mass” is what popular parlance tends to use and I follow that rather than explain the difference between mass, weight, force and load. I wish I could edit the video and correct the mistake, but that’s not possible with YouTube, hence this page.

Now if you want more detail, here it is.

This is what loadshare suspension should do:

Notice that both rear trailer tyres have similar compression despite the trailer being angled downwards quite significantly. This is an indication of good load-sharing.

You can see more on the Bruder suspension in my video here, including me changing the load-share system to get to almost 0kg towball mass, and even in the thumbnail you can see the load-share system at work:

Load-share is not new. Here is load-sharing on a Scammell 6×6 truck:

Here’s a 6×6 Pinzgauer in action with load-share suspension:

That’s what I had in mind when I talked about load-sharing. But, I got it wrong.

Now even those suspensions will ultimately run out of flex and leave all the weight balanced on one wheel, so there’s a limit to any load-sharing system.

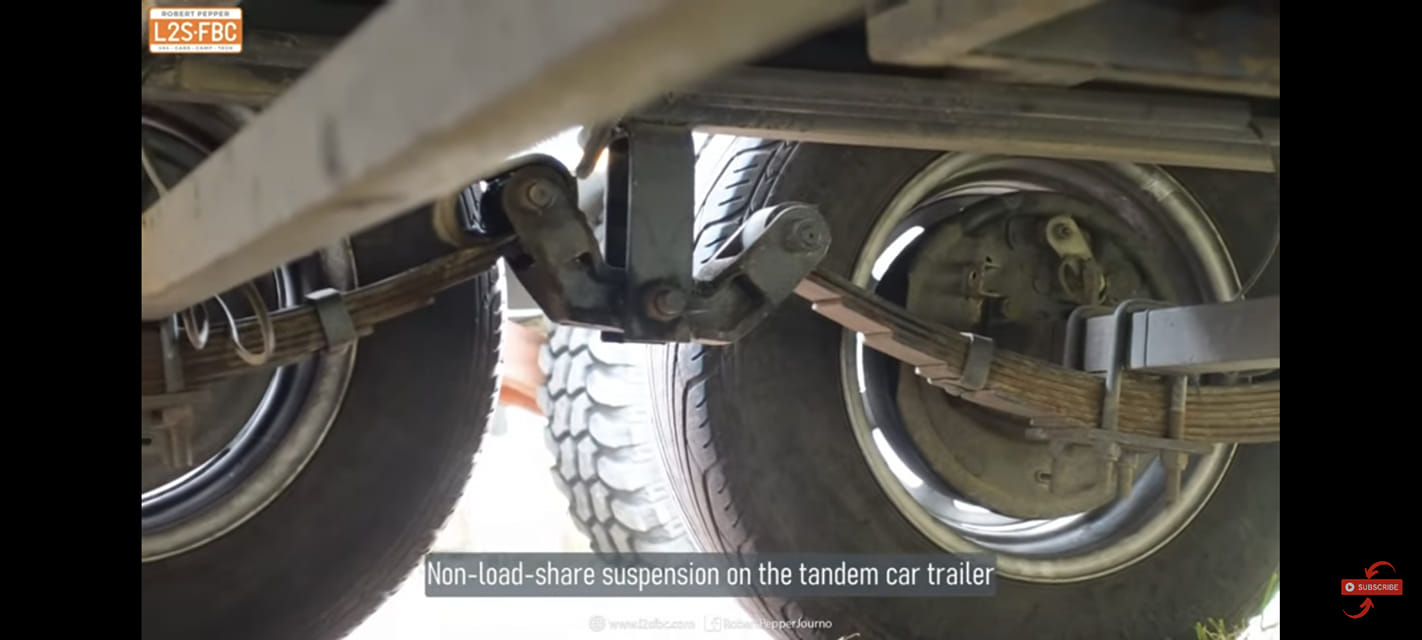

And, even a non-load-share system like the one below…

…does in fact load-share a bit over bumps as otherwise there’d be no point having two axles – no road surface is entirely flat. As one wheel is loaded, the suspension and tyre compress which moves that wheel up, placing load onto the other one which wants to extend its suspension and return its tyre to round. Here’s my car trailer with around 1100kg on it:

There is some load sharing going on, you can even see the link between the two axles has rotated, but look at the shape of the trailer’s tyres; the rear ones are far more compressed, the fronts are pretty round and suspension compression on the rear is far greater than the front. It would be interesting to do the same driveway with completely independent axles, and a “full” loadshare system. The photo does prove that the more load on that trailer, the better the load-sharing…but that’d be true of entirely separate axled-trailers too. Should also say this is a road trailer, not designed for offroad flexing and the fact it doesn’t load-share over a ditch-driveway isn’t important.

The video below includes me showing varying hitch loads with tandem and single-axle trailers, albeit with a model. There’s definitely no load-sharing suspension on the model trailer, and the results are as I get are consistent with my full-size tandem:

OK, now here’s the expert analysis from Daniel Nicholls:

That suspension setup is a rocker roller mate, it is full load sharing. An example of a non load sharing setup is a tandem slipper. At 5.25 you state that load sharing will behave the same as a single axle, this isn’t necessarily true as seen in your testing. With load sharing suspension it’s dependent on the load the trailer is carrying. Without any load in the trailer the friction between all of the suspension components that you’re trying to overcome will lead to the results you got. If you were to redo that test again with the trailer loaded you would find that it behaves the same as a single axle and the towball mass will depend on the portion of the trailers mass either side of the pivot point. Even so, your conclusions are correct.

I’m going to disagree re the max load point, having used that trailer a lot if it’s not level even by a little when loaded, the tyre deformation is quite different front-to-rear. And:

The reason the rear axle lifts is different to what caused the results you got. When you set up rocker roller suspension you weld the centre hanger in place then stretch the front and rear out to the limits of their travel keeping the rocker level, with no load on the system. From there, again under no load, as you rotate the rocker the pivot points come closer in to the centre, meaning the spring has to get longer. When you load the suspension up the spring flattens out at the roller moves up within the elongated spring eye. That lengthening allows the necessary space for the rocker to rotate and distribute the load evenly to both axles.

Now, the rocker assembly is also limited in its maximum rotation before it binds on the hanger or the elongated spring eye. In total you’ll get around 50mm vertical displacement from level (100mm height difference between the pivots on the rocker arms). Given the other end of the spring is fixed and the axle is halfway along, that means you’ll get 25mm of vertical travel at the axle, or 50mm total height difference between the two axles. So, as you drove up the 70mm blocks the issue was either the springs not being lengthened enough by the relatively low 1t tare of the trailer compared to their 3t rating and the rocker assembly running out of spring length, or the did get the appropriate length and you simply ran out of vertical travel on the rocker. Rocker roller is designed to load share over normal road surfaces. Things like undulations, driveways, speed bumps etc. Road obstacles of relatively limited vertical height.

If you’re driving up a gutter etc, yep, you’d expect that to be beyond the limit allowed by the geometry of the system and for one axle to load up. So that explains your wheel lifting. That’s not what gave you the results you got though. Lifting or lowering the coupling by 70mm shouldn’t have anywhere near enough rotation to cause the rocker to bind and the trailer tare should be high enough to flatten the springs enough for that small rotation, so best guess there is just friction. As you increase the load on the front axle by lowering the coupling that pushes the front axle up, which in turn pushes the rear down. Some of that force is lost to friction and without the weight on the trailer to overcome it, it will show a greater difference. And yep, the suspension under that Bruder is quite something. It’s not really a fair comparison though. Rocker roller isn’t meant to be an off-road suspension system. It’s not an apples for apples comparison. Same thing with the Pinzgauer etc. They’re just not made to do the same thing.

Note – the point is it’s not apples-to-apples.

To help illustrate as it’s far from obvious how it operates, this is a trailer I’m currently working on, setting up rocker roller suspension. If you have a look at the green circle you can see the roller is placed fully at one end in the spring eye. The red lines show the radius of the point on the rocker, demonstrating that to allow the suspension to displace vertically there has to be enough load to flatten the spring out. I also disconnected the other spring entirely to show that that’s as far as it can go. With no significant load you don’t get the spring flattened out enough to allow the suspension to move.